Semiconductor Process services – Sydney Nanoscience Hub, USYD

Client: University of Sydney

Location: Sydney, NSW

Project Scope: UHP Process Gas Delivery, Helium Recovery System, Life Safety & Cleanroom Fitout

Completion: 2018 – Ongoing

Sector: Advanced Research Infrastructure / Nanoscience & Quantum Research

Project Overview

The Sydney Nanoscience Hub is one of the most advanced research facilities in Australia, enabling pioneering work in quantum computing, nanotechnology, and fundamental physics. Umech has been engaged continuously since 2018 to deliver and maintain high-spec process gas and infrastructure systems critical to the facility’s operation.

This long-term engagement required specialist capability in ultra-high purity (UHP) gases, hazardous materials handling, cryogenic recovery, and research-grade life safety systems.

Umech provided a full design-and-construct scope across multiple laboratory zones and cleanrooms, including:

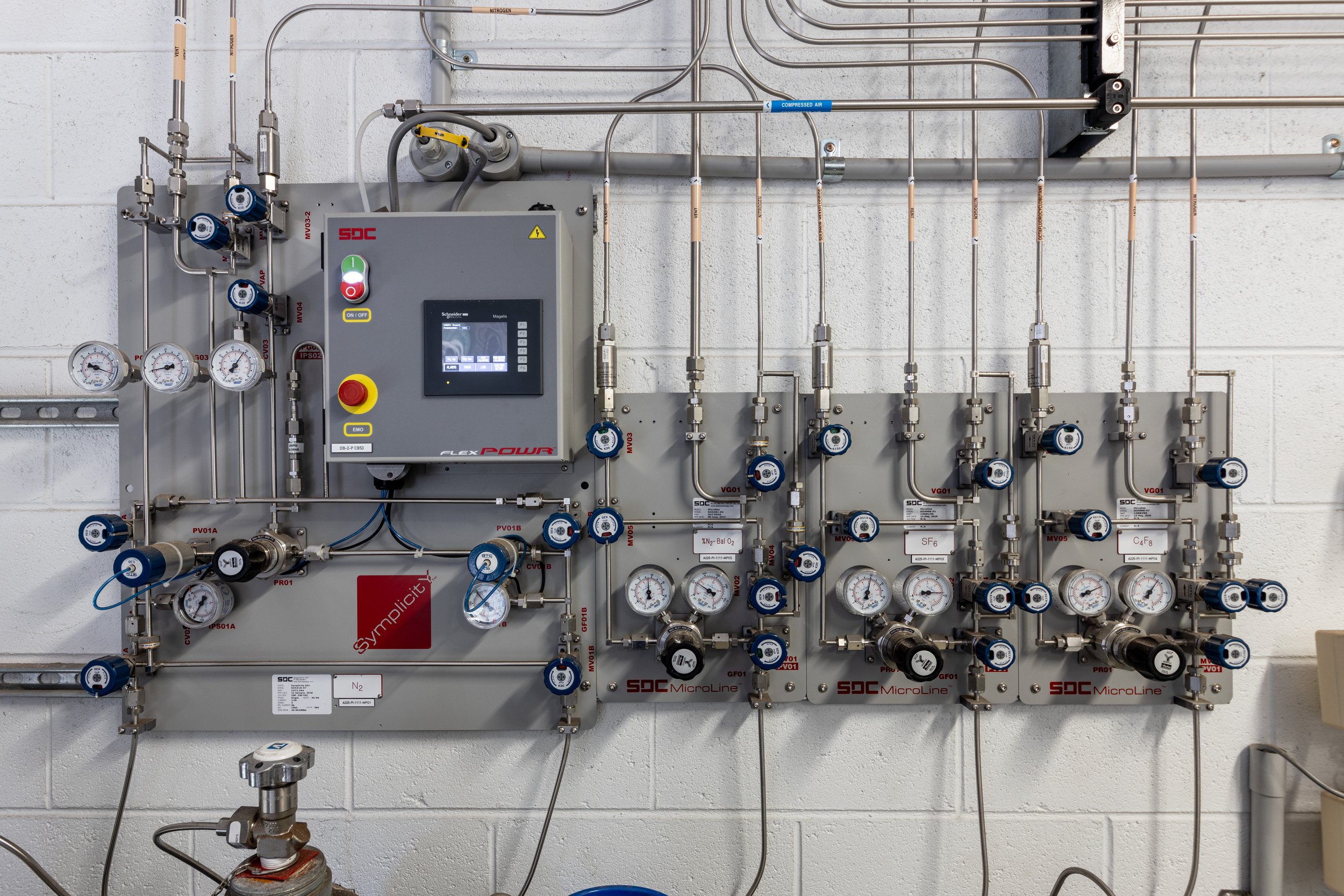

UHP Process Gas Delivery Systems:

5-valve auto-changeover gas manifolds for high-purity Argon, Oxygen, N₂ (6N), N₂O, and C₃F₈

Gas cabinets for Hydrogen, Silane, Ammonia, TEOS (liquid source)

Specialty gas systems piped to individual lab tools from bottled sources

Distribution of house gases: Compressed Air and Nitrogen

Helium Recovery System:

Supply and integration of Cryomech helium compressor and recovery skid

Installation of helium collection piping and compressor interlocks

Water, Vacuum, and Exhaust Systems:

Process Cooling Water (PCW) loops

Localized vacuum systems for tools and research modules

Exhaust management including CS Clean Dry Abatement Systems

Trade waste connection and tool exhaust

Life Safety & Detection Systems:

Fully compliant AS61508-rated toxic and flammable gas detection

Integrated oxygen depletion detection with control system logic

Fabrication of gas safety PLC panels and response interlocks

Technical Highlights

All UHP gas lines orbitally welded to ensure 99.999% purity

System design coordinated with cleanroom builders and lab tool vendors

Custom-fabricated manifold panels and liquid gas delivery skids

Redundant monitoring and control systems engineered for safety-critical zones

Real-time integration of tool states with life safety logic and exhaust sequencing

Outcome

Umech’s ongoing work at the Sydney Nanoscience Hub has enabled some of the most demanding experimental research environments in Australia. The systems installed operate reliably under high purity and high safety thresholds, supporting long-term quantum research and semiconductor process development.

Our ability to integrate specialty gas, cryogenics, life safety, and building services positions Umech as a trusted partner for elite research infrastructure.

Do you need semiconductor-grade gas systems for your cutting-edge research?

Umech partners with Australia’s top universities and tech labs to deliver ultra-high purity gas systems, cryogenic recovery, and life safety infrastructure built for precision, safety, and uptime.

Talk to our engineering team about your next high-spec research facility.