Quality

Quality ASSURANCE

Pharmaceutical Industries - High-Purity Gases & Systems - Ultra-high purity semiconductor fabs

Umech operate an extensive Quality Management System based on ISO:9001 with a focus on;

Continuous improvement - Customer satisfaction - Operational consistency

Let us develop customised Quality & Project Plans (QPP’s) or Inspection and tests plans (ITP’s) appropriate for your project. Our capabilities include Pharmaceutical industry level cGMP/GDP validation programs including IQ/OQ/PQ .

Pressure Testing

Umech pressure testing verifies the integrity of both standard purity and ultra-high purity (UHP) gas systems — so you can trust performance under the toughest conditions.

Stress testing: High-pressure fills

Leak detection: High-accuracy digital monitoring to capture even the smallest pressure loss

Line tracing: Fluid continuity checks to confirm gases flow exactly as designed

Whether commissioning a new system or validating existing infrastructure, Umech delivers pressure testing you can rely on — with the same precision and assurance trusted by Australia’s leading labs and fabs.

Helium Leak Detection

Umech provides the highest-accuracy leak detection available, giving you confidence that your system is sealed tight before it goes live. Our mobile helium mass spectrometers test to 1×10⁻¹¹ mbar∙L/s. Capable of detecting leaks a billion times smaller than a pinhole. This level of precision ensures:

Weld integrity in hazardous ultra-high purity gas systems

Zero contamination risk for semiconductor, pharma, and research applications

System reliability without costly downtime or rework

Both vacuum (inboard) and sniffer (outboard) helium leak testing are available, depending on your project requirements.

When system integrity is mission-critical, “good enough” isn’t good enough. Umech delivers assurance at the tightest leak detection thresholds in the industry.

Moisture Testing

Even trace levels of water vapour can compromise high-purity processes — causing corrosion, product contamination, and yield loss. Umech’s moisture testing services give you confidence that your systems meet the strictest specifications before start-up:

High-sensitivity detection: Cavity Ring-Down Spectroscopy (CRDS) H₂O analysis down to 12 ppb

Verification and calibration: Confirm dew point sensor accuracy and system response

Line contribution assessment: Identify and eliminate hidden sources of moisture within piping and fittings

System recovery checks: Verify that purging and conditioning restore required purity levels

From semiconductors to pharma, when dryness defines success, Umech delivers ppb-level assurance.

Particle Count Testing

Our team are experts in testing particle contamination to 0.3 - 10 𝜇um. Our test unit is designed to be integrated into your environmental monitoring program.

A totally sealed pharmaceutical grade Polycarbonate blend enclosure and is fully VHP compatible

Fully compliant to 21CFR part 11

Built-in cleanroom certification reports

NATA certified calibration

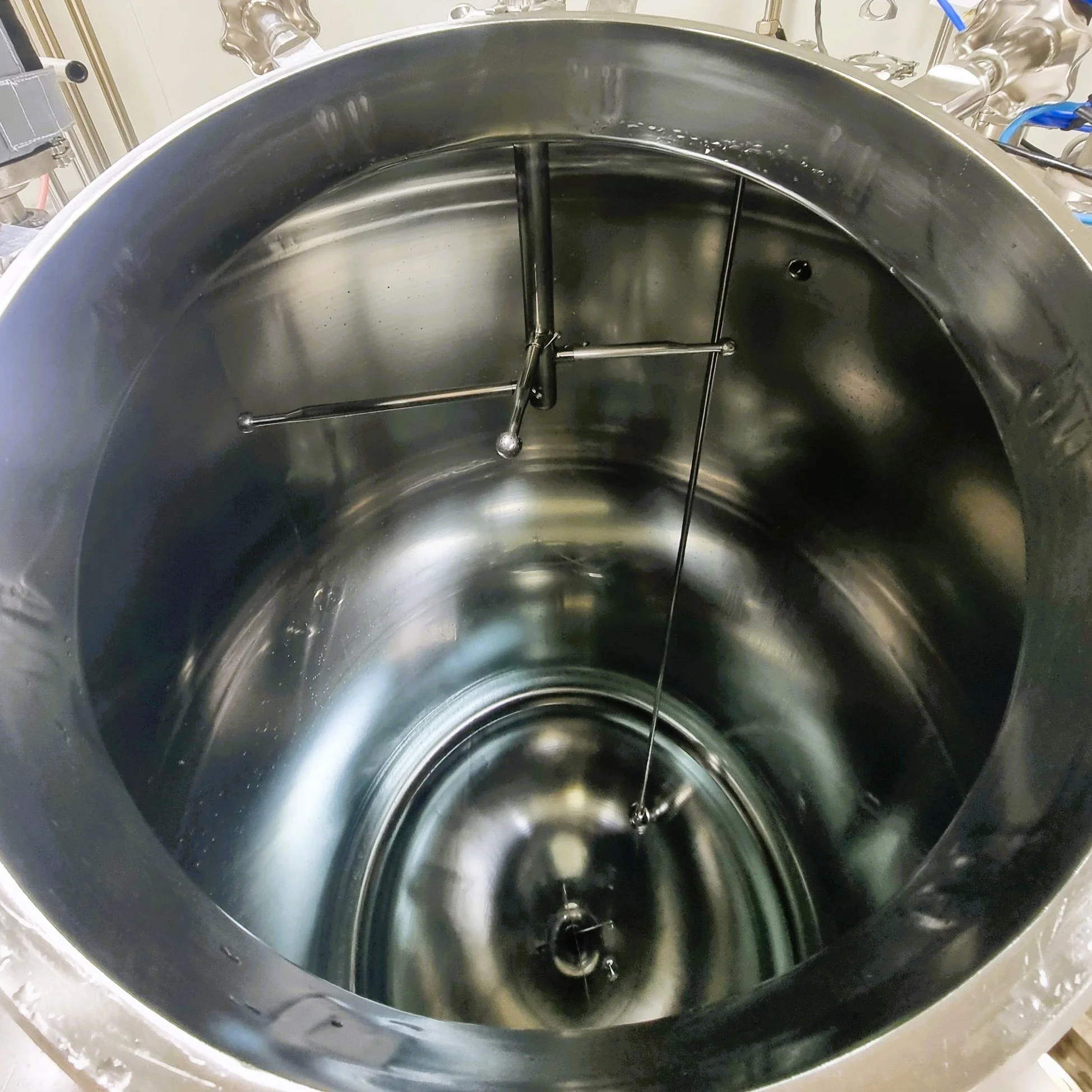

Derouging & Passivation

Umech’s custom built passivation skid can remove internal surface contamination from your piping system.

Nitric or Citric acid process

Safe, efficient and controlled passivation and flushing process for your facility

Pharmaceutical plants, vaccine manufacturing WFI and purified water systems.

Less risk of contamination-related production losses and unplanned system shutdowns

Commissioning & Validation

Our validation methodology is based around the Validation V-model and can be customised to suit various industries.

User Requirements Specification

Functional Specification

Technical specification

Design Qualification

Installation Qualification

Operation Qualification

Performance Qualification